Hamilton Beach Stack & Press Food Chopper with Glass Bowl

Hamilton Beach Stack & Press Food Chopper with Glass Bowl

This item consists of five components made of several distinct materials (glass, plastic, metal and rubberized plastic – in the cord). Four of the components are what I would consider “complex” items [made of multiple different materials.]:

- Clear Borosilicate Glass Vessel (Plastic, Glass and Metal)

- Clear Plastic Lid

- Blade (Metal & Plastic)

- Motor / Base (Metal & Plastic)

- Attached Electrical Cord (Metal & Plastic)

Note: Generally when folks send me things for testing I request that the box contain no more than 9 simple items and one complex item, for more info on the testing I do with my followers, click here.

Click here for an Amazon affiliate link* for this exact item.

To learn more about XRF testing, click here.

As I would have anticipated with an item like this (newly manufactured, primarily glass and hard plastic) all components were negative for Lead (Pb), Cadmium (Cd), Arsenic (As), and Mercury (Hg).

To see more Hamilton Beach brand products I have tested, click here.

Below are the full XRF readings for each component (when tested using “Consumer Goods” mode). For each component tested multiple tests were done to confirm the levels (for 30 seconds or one minute per test). For any element/metal detected, levels below 90 ppm are generally considered “trace” and not an additive to the product.

Electrical Cord

Tested Component #ONE: Black Plastic Element of Electric Cord

- Antimony (Sb): 5,794 +/- 169 ppm**

- Bromine (Br): 13 +/- 7 ppm

- Zinc (Zi): 377 +/- 52 ppm

- Iron (Fe): 182 +/- 103 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

**Antimony is commonly found in new electrical cords.

Tested Component #TWO: Metal Prong of Electrical Cord, Note: prong does not fill XRF detection window fully, and the total numbers (in ppm) for metals detected might be higher if it did, however the general makeup of the component is accurate within the range of testing of the XRF.

- Zinc (Zi): 250,800 +/- 32,000 ppm

- Copper (Cu): 489,000 +/- 56,000 ppm

- Nickel (Ni): 83,000 +/- 6,400 ppm

- Iron (Fe): 576 +/- 222 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Accessible Components of Base (Motor)

(Accessible without destruction or disassembly)

Tested Component #THREE: Black Hard Plastic Elements of Base:

- Barium (Ba): 367 +/- 125 ppm

- Antimony (Sb): 118 +/- 30 ppm

- Bromine (Br): 167 +/- 8 ppm

- Zinc (Zn): 264 +/- 18 ppm

- Iron (Fe): 72 +/- 26 ppm

- Titanium (Ti): 1,814 +/- 352 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Tested Component #FOUR: Silver Colored Metal Component of Base: Stainless Steel 439/40.:

- Chromium (Cr): 161,000 +/- 1,600 ppm

- Nickel (Ni): 1,149 +/- 369 ppm

- Iron (Fe): 830,000 +/- 2,500 ppm

- Vanadium (V): 1,238 +/- 449 ppm

- Manganese (Mn): 5,505 +/- 1,147 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Tested Component #FIVE: White Plastic Center Piece of Base (Note: This piece was difficult to test with the XRF due to geometry, so results might be different if base was disassembled/with destructive testing. However results were as anticipated, given the type of material.):

- Bromine (Br): 258 +/- 13 ppm

- Zinc (Zn): 62 +/- 16 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Tested Component #SIX: Center Metal Spindle of Base (does not fill up full scope of instrument due to size/shape.):

- Chromium (Cr): 161,600 +/- 1,800 ppm

- Copper (Cu): 1,241 +/- 328 ppm

- Nickel (Ni): 4,036 +/- 604 ppm

- Iron (Fe): 822,900 +/- 2,900 ppm

- Vandium (V): 1,244 +/- 511 ppm

- Nb: 1,640 +/- 118 ppm

- Manganese (Mn): 3,254 +/- 1,253 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Tested Component #SEVEN: Gray Plastic Feet of Base:

- Barium (Ba): 1,253 +/- 348 ppm

- Zinc (Zn): 125 +- 27 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Clear Glass (Borosilicate) Blender Jar

Tested Component #EIGHT: Clear Glass Elements of Jar

- Vanadium (V): 829 +/- 130 ppm

- Titanium (Ti): 1,621 +/- 212 ppm

- Barium (Ba): 2,725 +/- 103 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

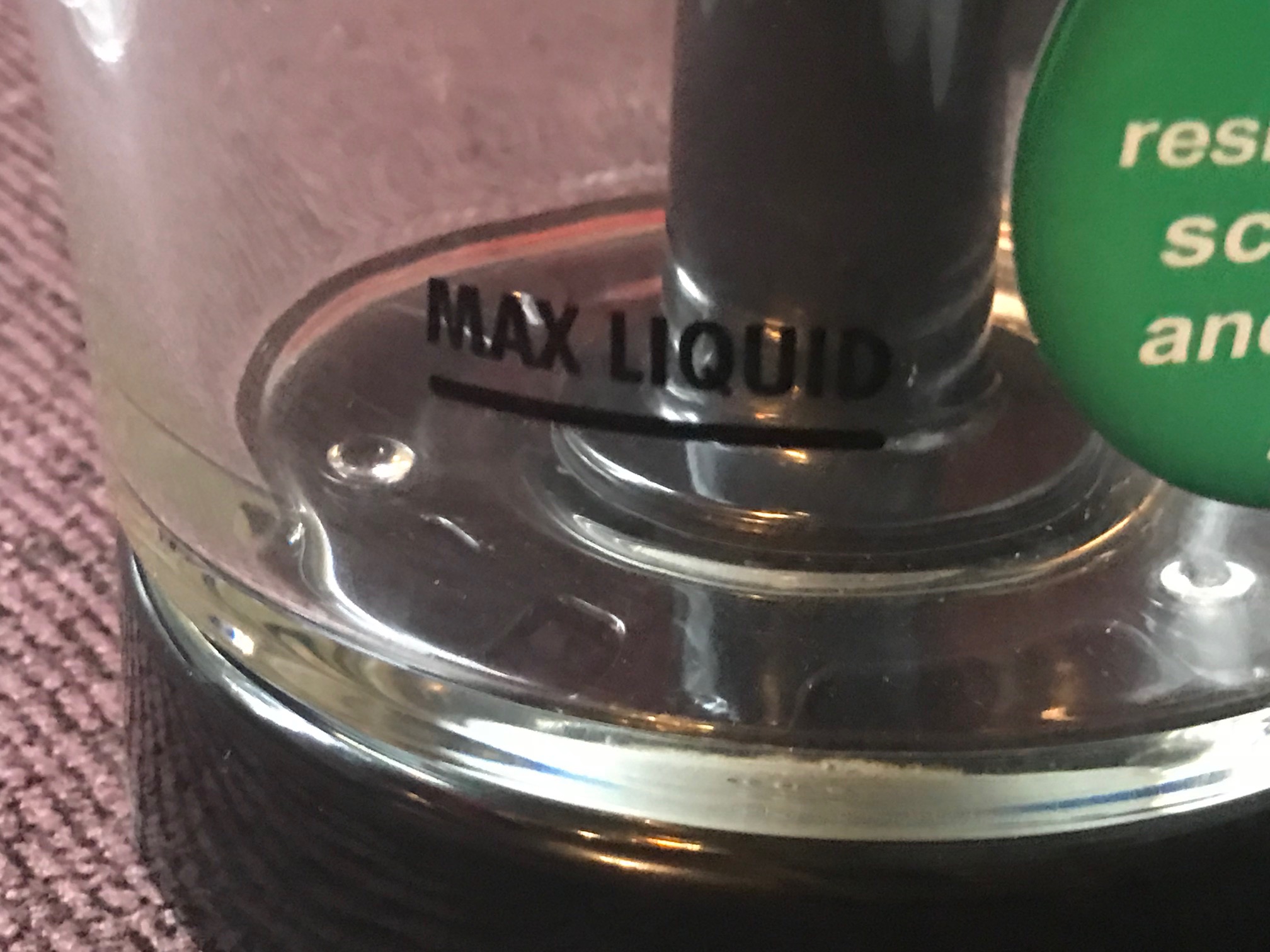

Tested Component #NINE: Black Painted Fill Marking on Jar

- Barium (Ba): 2,777 +/- 110 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Tested Component #TEN: Black Hard Plastic Element of Jar

- Barium (Ba): 205 +/- 116 ppm

- Bromine (Br): 28 +/- 3 ppm

- Zinc (Zn): 157 +/- 13 ppm

- Nickel (Ni): 15 +/- 9 ppm

- Iron (Fe): 41 +/- 20 ppm

- Titanium (Ti): 800 +/- 275 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

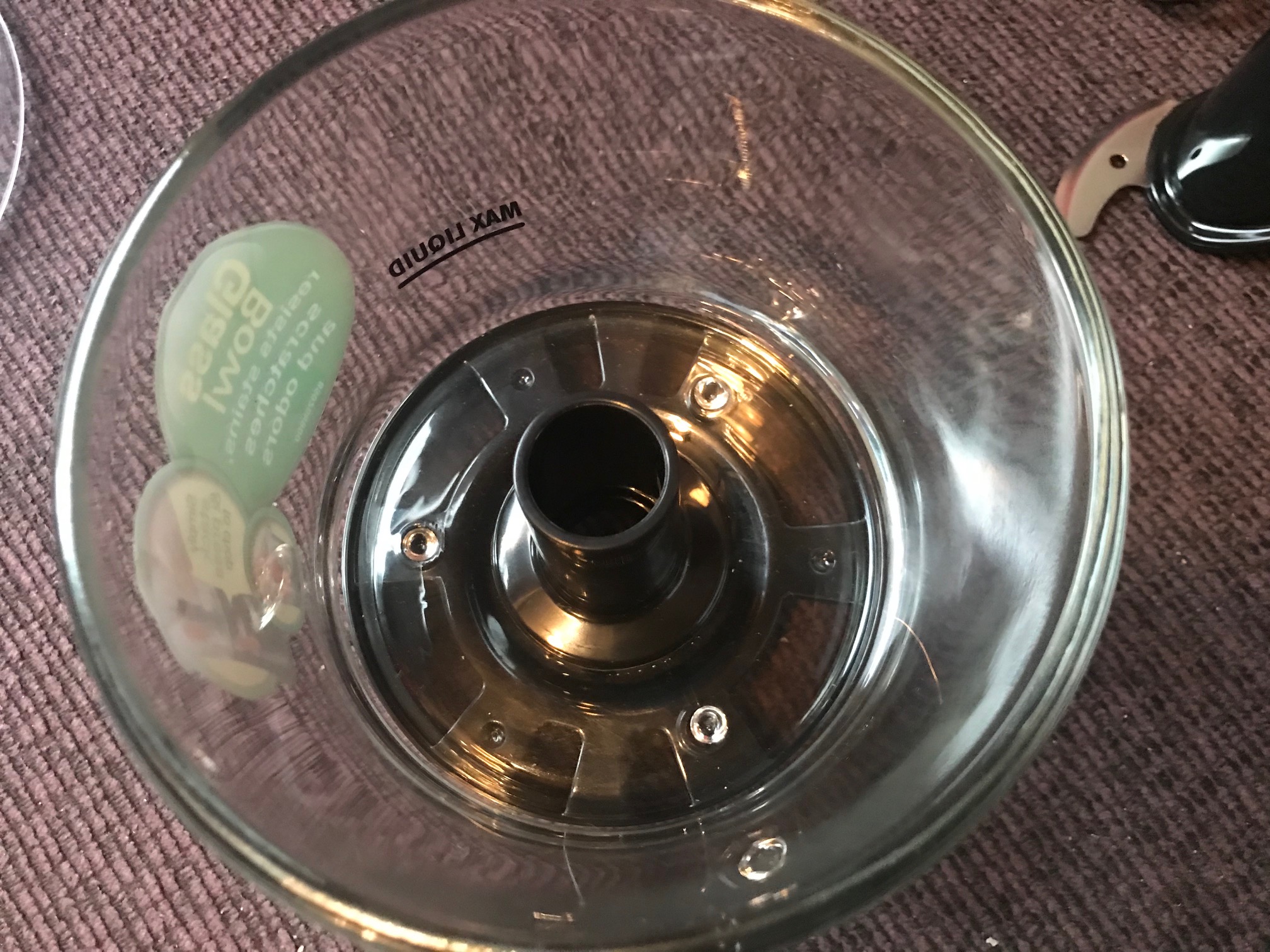

Tested Component #ELEVEN: Screws on Bottom Base (holding glass on to base). Note: screws do not go through to food surface of vessel, they are encased in what I would describe as a glass bubble (see images below).

- Barium (Ba): 1,195 +/- 124 ppm

- Chromium (Cr): 26,400 +/- 500 ppm

- Bromine (Br): 16 +/- 11 ppm

- Zinc (Zn): 98 +/- 46 ppm

- Copper (Cu): 2,463 +/- 155 ppm

- Nickel (Ni): 5,889 +/- 242 ppm

- Iron (Fe): 86,800 +/- 1,800 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Metal and Plastic Blade Component

Tested Component #TWELVE: Metal of Blade, Steel 410/16/20

- Chromium (Cr): 137,300 +/- 1,800 ppm

- Iron (Fe): 854,100 +/- 3,100 ppm

- Manganese (Mn): 4,776 +/- 1,372 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Tested Component #THIRTEEN: Black Plastic of Blade Component

- Bromine (Br): 5 +/- 2 ppm

- Zinc (Zn): 47 +/- 9 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Clear Plastic Lid Component

Tested Component #FOURTEEN: Clear Plastic

- As expected this component did not test positive for any metals when tested with an XRF instrument

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

Tested Component #FIFTEEN: Black Writing On Clear Plastic (see image below)

- Nickel (Ni): 23 +/- 14 ppm

- Lead (Pb): Non-Detect (ND)/Negative

- Arsenic (As): Non-Detect (ND)/Negative

- Cadmium (Cd): Non-Detect (ND)/Negative

- Mercury (Hg): Non-Detect (ND)/Negative

To see more blenders and blender components I have tested, click here.

NOTE: XRF testing is recognized by the Consumer Product Safety Commission as an acceptable and accurate way to screen consumer goods for potential toxicants. The Niton XL3T model that was used for testing this product tests down to single digit parts per million for any metals detected. The work I do is for advocacy purposes only, as a screening tool for toxicants. I report the other metals I find “just for fun”, as I find it interesting to know exactly what consumer goods are made of!

The testing I coordinate is not done in a lab (and does not represent a lab/is not affiliated with a lab) and no formal reports (other than the results as shared in these articles) are created through my work. That said the results are accurate and replicable by others using the same instrumentation (and also generally by others using digestive or destructive testing as long as the components are tested separately.)

Thank you for reading this work and sharing it in your communities!

As always, please let me know if you have any questions.

Tamara Rubin

#LeadSafeMama

*Links on this page may be Amazon affiliate links. If you purchase something after clicking on an affiliate link I will receive a small percentage of what you spend at no additional cost to you. Thank you for supporting my advocacy work in this way.

Never Miss an Important Article Again!

Join our Email List

You are So thorough!! I might get this one, thank you!

Thank you. I am glad you appreciate it! Each post like this is quite a bit of work 🙂 [I’ve not done many blender / small appliance posts as a result.] I always wonder if I am the only one who is a tech geek when it comes to getting into the detail on the XRF readings. Please let me know if you ever have any questions!

Tamara

Hi,I could not find this in you amazon store . Do you recommend buying this blender?

Hi Fenny – I haven’t used it or tried it and I have only tested this one example, which is why it is not in my store. It looks like it is likely a good choice tho.

Tamara

Hi Tamara, thank you for the swift reply , I was planning to use this to blend my baby food as I am not comfortable with using other babyfood blender .Could you perhaps recommends me if you know any .Thank you!

This one is no longer available. The new version has a plastic bowl.

🙁

Do you think the plastic bowl is safe?