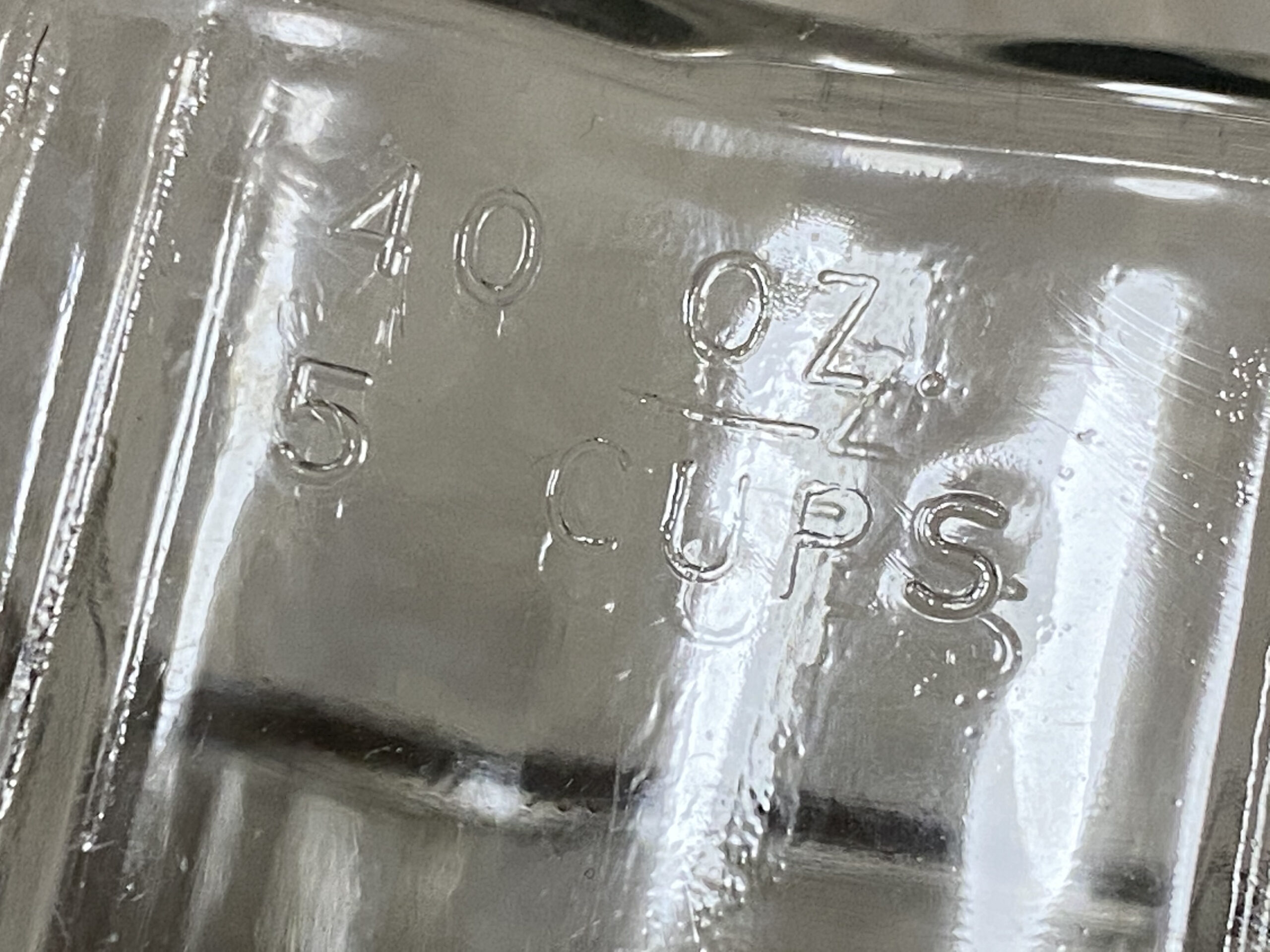

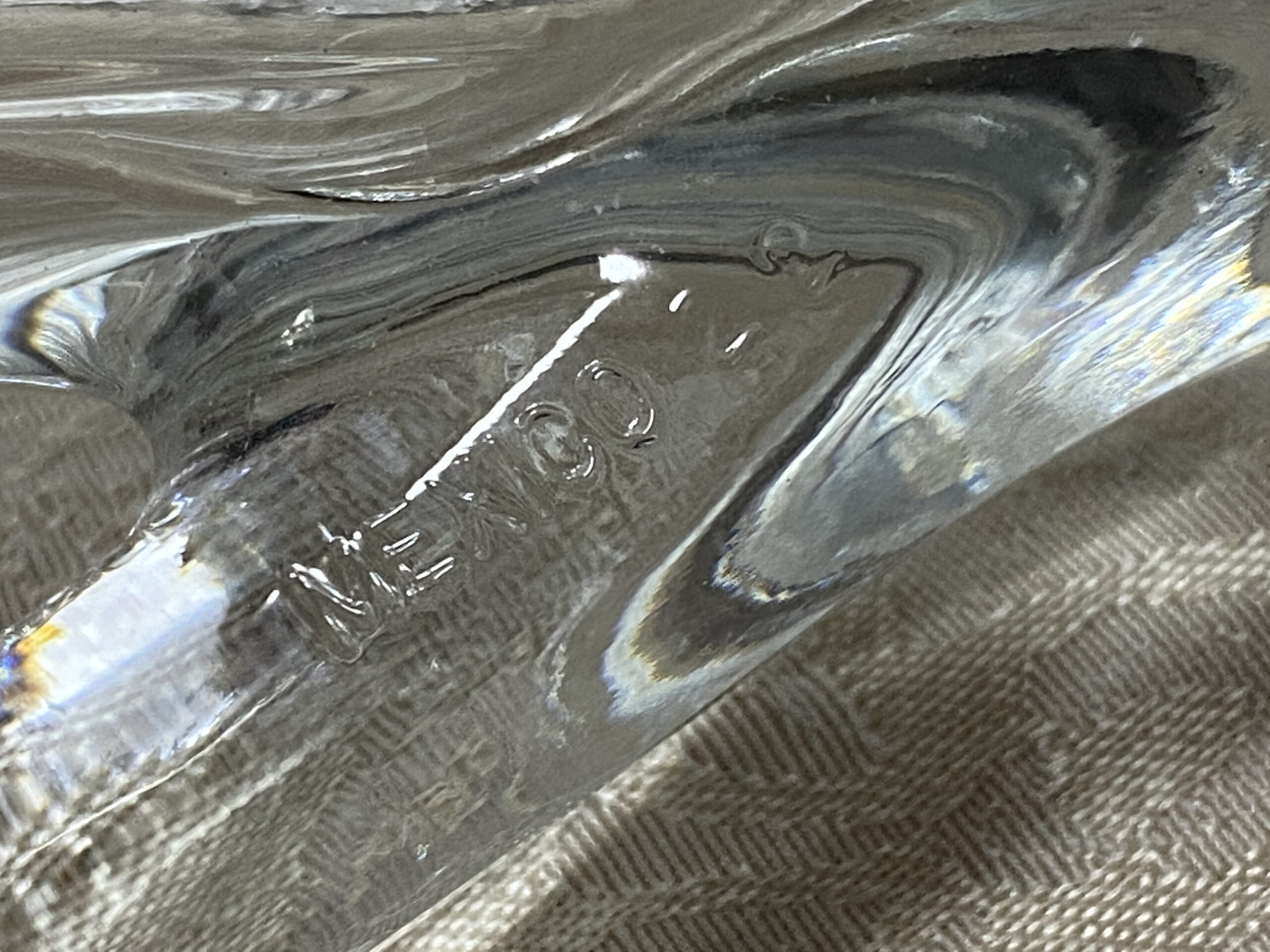

40 oz. Borosilicate Glass (“Boroglass”) Pitcher for Vintage Style Blender (Made in Mexico): Lead found in exterior metal components.

Introduction:

Tamara Rubin is a Federal award winning independent advocate for consumer goods safety and childhood Lead poisoning prevention. She is also a mother of Lead-poisoned children. She began testing consumer goods for toxicants in 2009, and was the parent-advocate responsible for finding Lead in the popular fidget spinner toys in 2017. She uses XRF testing (a scientific method used by the Consumer Product Safety Commission) to test consumer goods for metallic toxicants (including Lead, Cadmium, Mercury and Arsenic). To read more about the testing methodology employed for the test results reported on this blog, please click this link.

XRF Test Results for the borosilicate glass pitcher pictured

Test Result Set #1: Glass of pitcher

60-second test on handle of pitcher

- Lead (Pb): non-detect

- Cadmium (Cd): non-detect

- Mercury (Hg): non-detect

- Bromine (Br): non-detect

- Chromium (Cr): non-detect

- Copper (Cu): 15 +/- 7 ppm

- Zirconium (Zr): 265 +/- 4 ppm

- No other metals detected

Test Result Set #2: Glass of pitcher

30-second test on foot of pitcher

- Lead (Pb): non-detect

- Cadmium (Cd): non-detect

- Mercury (Hg): non-detect

- Bromine (Br): non-detect

- Chromium (Cr): non-detect

- Iron (Fe); 74 +/- 42 ppm

- Zirconium (Zr): 281 +/- 6 ppm

- No other metals detected

Test Result Set #3: Glass of pitcher

60-second test on body (side) of pitcher

- Lead (Pb): non-detect

- Cadmium (Cd): non-detect

- Mercury (Hg): non-detect

- Bromine (Br): non-detect

- Chromium (Cr): non-detect

- Iron (Fe); 46 +/- 29 ppm

- Zirconium (Zr): 284 +/- 4 ppm

- Palladium (Pd): 2 +/- 1 ppm

- No other metals detected

Continue reading below the images

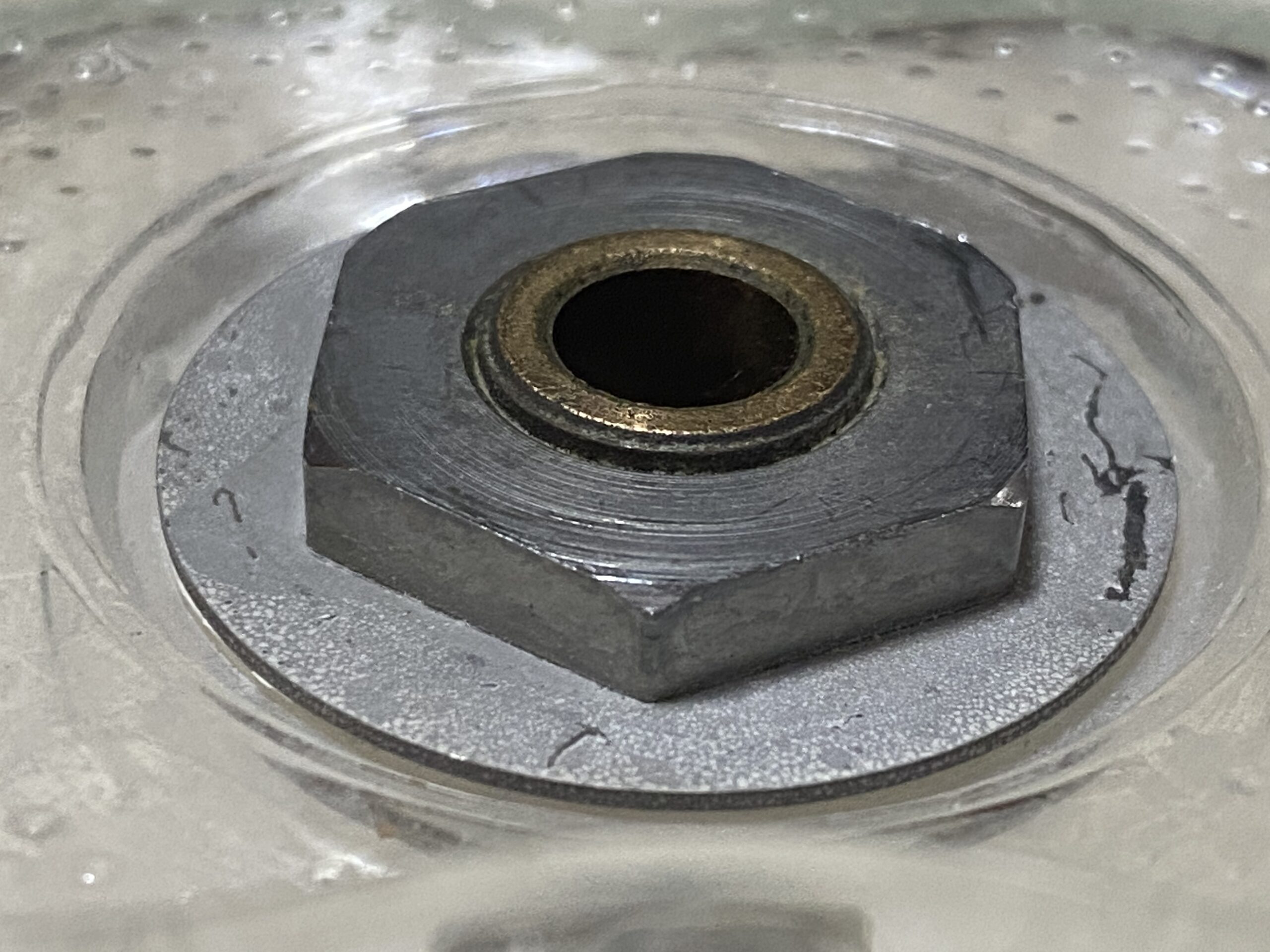

The three images below are of the outside bottom of the pitcher

Test Result Set #4: Focus on gray metal hexagonal nut on bottom of pitcher

– this component is not fully isolated given the geometry of the configuration of the bottom of the pitcher

60-second test

- Lead (Pb): 2,520 +/- 107 ppm

- Cadmium (Cd): non-detect

- Mercury (Hg): non-detect

- Bromine (Br): non-detect

- Chromium (Cr): 6,422 +/- 166 ppm

- Manganese (Mn): 220 +/- 70 ppm

- Iron (Fe); 6,372 +/- 114 ppm

- Cobalt (Co): 261 +/- 74 ppm

- Nickel (Ni): 713,300 +/- 700 ppm

- Copper (Cu): 259,600 +/- 600 ppm

- Zinc (Zn): 7,004 +/- 238 ppm

- Molybdenum (Mo): 527 +/- 64 ppm

- Indium (In): 26 +/- 17 ppm

- Tin (Sn): 3,521 +/- 61 ppm

- No other metals detected

Test Result Set #5: Focus on golden metal circle bottom of pitcher

60-second test. Given the geometry of the base of the pitcher this reading also includes some of the metal of the gray hexagonal nut and some of the Lead (and other metals) detected could be coming from that component and not the circular component itself.

- Lead (Pb): 242 +/- 72 ppm

- Cadmium (Cd): non-detect

- Mercury (Hg): non-detect

- Bromine (Br): non-detect

- Chromium (Cr): 551 +/- 152 ppm

- Iron (Fe); 1,284 +/- 127 ppm

- Nickel (Ni): 32,900 +/- 400 ppm

- Copper (Cu): 864,800 +/- 900 ppm

- Zinc (Zn): 2,309 +/- 196 ppm

- Molybdenum (Mo): 1,002 +/- 106 ppm

- Indium (In): 153 +/- 55 ppm

- Tin (Sn): 96,200 +/- 500 ppm

- No other metals detected

Test Result Set #6: Focus on gray metal circle bottom of pitcher

60-second test. Not fully accessible – same considerations as above in #5

- Lead (Pb): 601 +/- 53 ppm

- Cadmium (Cd): non-detect

- Mercury (Hg): non-detect

- Bromine (Br): non-detect

- Chromium (Cr): 84,000 +/- 500 ppm

- Vanadium (V): 657 +/- 138 ppm

- Manganese (Mn): 4,315 +/- 244

- Iron (Fe); 190,700 +/- 600 ppm

- Cobalt (Co): 815 +/- 283 ppm

- Nickel (Ni): 586,200 +/- 1,000 ppm

- Copper (Cu): 124,700 +/- 600 ppm

- Zinc (Zn): 4,715 +/- 169 ppm

- Molybdenum (Mo): 2,420 +/- 71 ppm

- Tin (Sn): 499 +/- 26 ppm

- Barium (Ba): 114 +/- 71 ppm

- No other metals detected

NOTE: In the absence of destructive testing, interior metal components of the pitcher are not accessible for testing using XRF technology. All accessible components were tested multiple times to confirm the test results for the item pictured.

Continue reading below the images of the interior hardware at the bottom of the pitcher

In conclusion

In conclusion

The interior hardware of this glass pitcher (pictured above) has a hexagonal nut at the bottom of the stack very similar to the one on the exterior that tested positive for a fairly significant amount of Lead [Reading #4 above.] This hardware is fixed in place and is not apparently readily removable.

Given I have previously found this sort of hardware on the inside of older and vintage (pre-2011) blender pitchers (of different brands and models) to test positive for unsafe levels of Lead, in the absence of destructive testing it is my opinion that one or more of the food-contact hardware components in this pitcher are likely to also test positive for unsafe levels of Lead. As a result I would not recommend continuing to use a pitcher like this for food use purposes (again, in the absence of destructive testing or possibly leach testing done to confirm or refute the safety of the vessel for food use purposes.) This is, in fact, NOT a vintage pitcher but a vintage-style pitcher.

Thank you for reading and for sharing my posts. As always, please let me know if you have any questions.

Tamara Rubin

#LeadSafeMama

Never Miss an Important Article Again!

Join our Email List

In conclusion

In conclusion

Tamara

What glass pitcher with a lid would you recommend?